Infrared Optics

We supply the very best infrared optics for a diverse range of applications across Short-Wave (SWIR), Mid-Wave (MWIR), and Long-Wave (LWIR) spectra. Using diamond turning and other conventional fabrication techniques, along with tightly controlled processes we strive to deliver your components on time and on budget — and always meeting or exceeding your specifications. Our industry-leading fabrication, project documentation, and data deliverables ensure your success, no matter the application.

Hardin Optical produces infrared optical components for defense, medical and commercial applications. Our extensive list of successes includes optical hardware in both small and large volumes to meet the needs of our customers and deliver beyond their expectations.

Shapes & Configurations

- Spheres, Apsheres, Windows, Arrays, Non-Rotationally Symmetric free forms, and Diffractives.

- Sizes from .5mm to 350mm depending on optical design

- High slope, High aspect ratio, and High efficiency refractive optics.

- Surface finishes at 2.5nm or better depending on optical design

- 1/8 wave or better depending on optical design

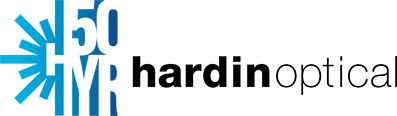

Diverse Materials

- Metals including Aluminum, Copper, Electroless Nickel, Silver, Brass, Gold, Bronze, and Tin

- Crystals including Germanium, Silicon, Zinc Selenide, Zinc Sulfide, Calcium Fluoride, Magnesium Fluoride, and Barium Fluoride

- Chalcogenide Glasses including AMTIR, IRG, and IG variations.

- Polymers including Acrylic, Nylon, Polycarbonate, and Polystyrene

- IR grade Fused Silica, and Sapphire

Prototype to Production

- Partnering Solution Based Approach from Initial Concept to High Volume Production

- Engineering and Design for Manufacturability Support

- Continuous Improvement Towards Long Term Goals

- Focused Execution to meet Customer Commitments

- Industry Leading Data Packages

Ultra-Precision Processing

- State of the art Diamond turning facility

- High Speed CNC Generating and Finishing-Ideal for the high-volume manufacturing

- Conventional loose abrasive Grinding and Polishing

- Double sided lapping and polishing

- Continuous Polishing

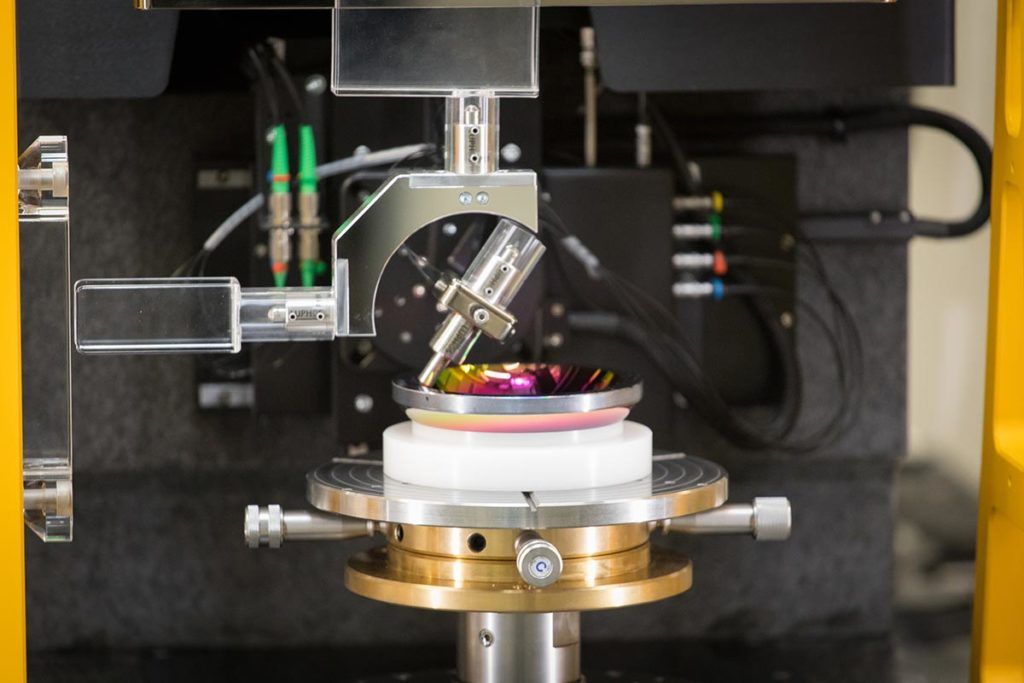

State-of-the-Art Metrology

- Talysurf PGI

- Zygo New View White Light Interferometer

- Various laser interferometers Including 4in and 6in Zygo Verifire

- New in 2018 LuphoScan 260- Fast non-contact 3d form measurement with +/- 50nm accuracy

Customer Focused

We listen to and collaborate with our customers as their partner, make meaningful commitments to them, and meet those commitments. We have an amazing team at Hardin, holding one another accountable to time tested core values and we believe it’s ultimately reflected in our products and relationships with our customers.

Overview

- Including but not limited to:

- Infrared Materials:

- Crystalline: Ge, Si, ZnSe, ZnS, CaF2, BaF2, MgF2

- Metals: Al, Ni, brass, hard copper

- Chalcogenide Glasses: IRG, IG, AMTIR

- Glasses: IR Grade fuse silica, N-BK7, Sapphire

- 0.5mm – 350 mm diameters

- Wedge ≤ 0.003mm

- <=λ/8 P-V Surface Accuracies

- < 2.5nm RMS Surface Roughness

- Geometries include on and off-axis: spherical, aspherical, windows, toroidal, cylindrical, arrays, and other free-form configurations

- All specifications subject to optical design and material.